Furniture is a leader in circularity, use this to your advantage as a purchaser!

The Furniture category is leading many other products and services in terms of circularity. This offers many opportunities for buyers who want to procure sustainable and circular furniture. The Fair Furniture Group – with companies like Vepa and Eromesmarko – is a great example of such a front runner that puts circularity 100% at the core of their operations. In this article, we speak to Frank Bouma, Chief Sustainability Officer at the Fair Furniture Group. During our discussion, we look at developments within the sector, the role of circularity and opportunities and tips for purchasers.

Can you tell us what the Fair Furniture Group does?

The Fair Furniture Group is a holding of family businesses that makes and supplies sustainable furniture for offices, education and other markets. We offer this from various brands. Our furniture is sustainable and circular, for example by using bio-based materials, refurbishing existing furniture or making innovative and fully demountable furniture. Production takes place at our four specialised production sites in the Netherlands and one in the UK. We set these up as sustainable as possible, where even the powder coating plants run partly on electricity and hydrogen from natural energy sources. We have also entered into various partnerships and offer people distanced from the labour market a workplace in our factories. Our designers design from circular design principles and we have set up a returns programme for our furniture with partners in the supply chain. We have a Circular Centre fully integrated in our production process, where we give used furniture from the market a new life. In doing so, we are committed to reuse, value-preservation and waste reduction.

What was important in your organisation’s transition to circularity?

We work with a different revenue model. We add value to raw materials, make new products from existing materials and develop new furniture from bio-based materials such as hemp and flax. This is because you make the biggest impact with circular raw materials.

What makes the furniture category unique?

Everyone knows furniture and you see it everywhere. That makes it a logical starting point for circular initiatives. The unique aspect of furniture, compared to road construction, for example, is that the reason for buying new furniture is often aesthetic or functional rather than necessity. This provides a good basis for reuse and fits well within circular initiatives. The NEN standard developed for circular furniture can also be applied to other categories, expanding the impact of circular practices.

Is the market ready for this?

The market has changed from the past, where procurement used to be mostly transactional. We see that today there is a growing awareness and desire for sustainability and circularity, but some people do not always fully understand what this means. There are now more ways to approach circularity, not only in procurement, but also in looking at the total cost of ownership. Therefore, we don’t just deliver a product, but work together with the customer, by starting a conversation. However, companies don’t always know exactly what they are asking for and this can lead to confusing labels and overvaluation of certain sustainability labels.

How do you deal with this advantage in knowledge?

It is important to speak the same language, both internally and externally, to facilitate the conversation with purchasers and to promote consistency within the chain. To this end, we developed the NEN guideline NPR8313 for circular furniture together with stakeholders such as fellow manufacturers, purchasers and consultants. This standard helps define circularity and ensures that all stakeholders speak the same language. Part of the standard includes a model with six circular strategies to design and recognise circularity. These include the long-term use of products, the ability to repair and disassemble, and minimising emissions and resource exhaustion. In doing so, the standard provides a measurement method, where it is crucial to disseminate this information widely within the market, given the large knowledge differences between purchasers and manufacturers, for example.

What do you think is the biggest challenge?

I think the biggest challenge lies in finding a balance between making an impact on policy goals and policy perspectives. This means that when there is a lot of information, it should also be understandable for everyone. It should not be unnecessarily complicated, but rather as simple as possible. The goal is to make knowledge standards deployable and easily transferable.

Can you give a concrete example from practice?

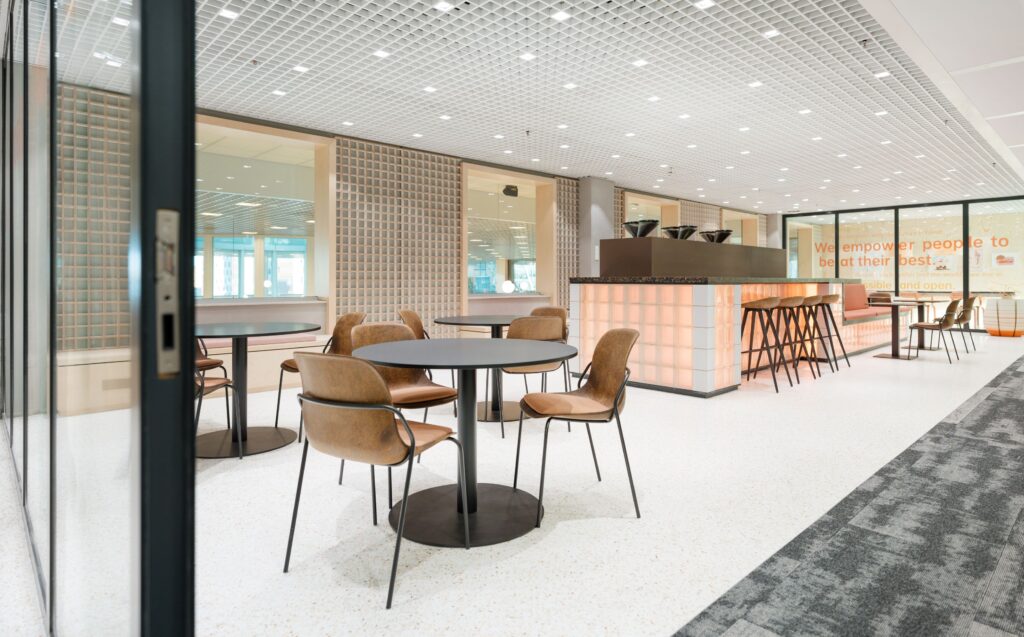

A great example is the refurbishment of Nationale Nederlanden’s office buildings in The Hague and Rotterdam. In this project, we took on the management and implementation of the furniture: from drawing up the project plan, to delivery and maintenance. This involved the refurbishment of an office space at two locations, totalling more than 37,000 m2 over 24 floors. In this project, we reused 70% of the existing furniture, 20% was sourced second-hand and 10% was produced new and circular. This makes the office 100% circular with 0% waste. Reuse was preferred over recycling furniture or buying new products. Everything that temporarily left the building was given a new use in the new working environment. Any ‘new’ products were made from waste, for example an old fridge that was transformed into a conference table.

Do you have any tips for purchasers?

My advice to purchasers is to be open to new possibilities. After all, much more is possible than you think. Collaboration is essential here, so use the expertise of suppliers and immerse yourself in circularity. In addition, be critical. During tenders, it is important to let the potential cooperation partner explain what is possible; this helps to make better decisions than just based on price. In fact, buyers should also work with suppliers on innovation and circularity. It is challenging, but it also becomes more fun and creates equal partnerships.

As a purchaser it can be challenging, but that also makes it more fun.

Frank Bouma

We also encourage exploratory purchasers to start a conversation and explore the market. Even within the government, where procedures are strict, market exploration is perfectly fine. Due to this, possibilities are already considered in the early stages of the procurement process.